Technology benefits

- Capability of multi-stage hydraulic fracturing at any intervals of the cemented production liners and casings of 4.13”– 5.5” in diameter.

- Ability to change the setup of the perforation assembly. The perforation section can vary from 19.69” to 236.2”.

- The number of operations is not limited.

- The length of the channel between the well and the formation from 27.56” to 41.34”.

- Creation of a significant zone of formation drainage, increase in starting production rates.

- Ability to conduct a cycle of repeated multi-stage fracturing operations in existing and previously unstimulated production zones.

- Unlimited time delay between activations of the assembly components.

- Reduced well downtime.

- Reduced expenses for provided services.

Technology Description

- Use the Wireline PCE for well intervention allows to perform the jobs without full well killing.

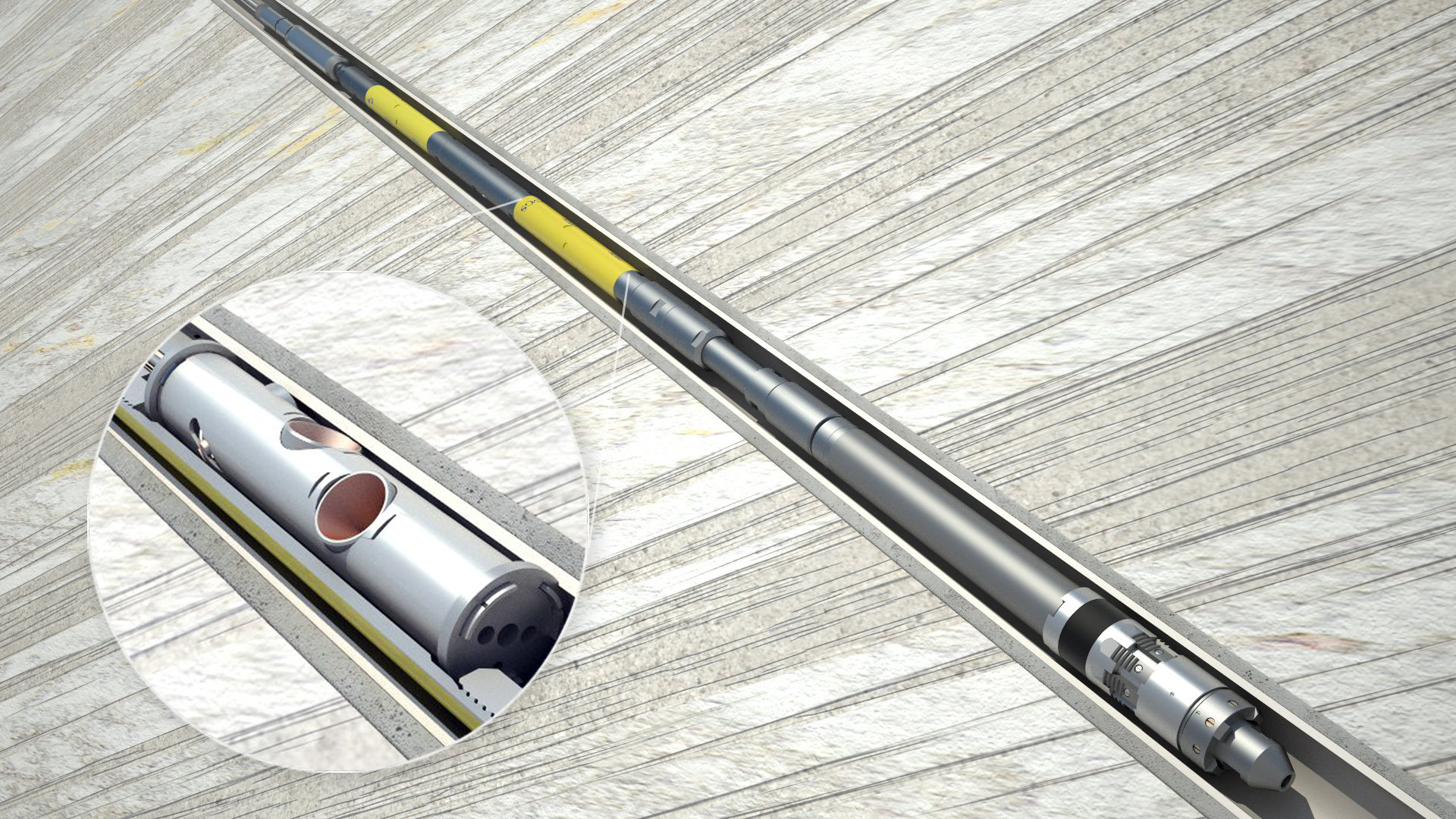

- Delivery of perforating assembly to a stated well interval is carried by using a geophysical cable.

- The assembly is lowered by gravity trough the lift of hydraulic fracturing setup in the vertical section of the well with descent speed up to 3.1 miles per hour.

- The travel of the assembly in the horizontal section of the well is sustained by piston effect caused by the pump of hydraulic fracturing fleet with a flow rate 38.8 to 56.5 SCFM.

- The assembly is pumped 50-65 feet further down the installation location of the packer plug in order to take out the sag of the wire and to make precise positioning of the assembly.

- Installation of a packer plug takes place followed by detaching from the perforation assembly, and then sequential cumulative perforation of several intervals is performed using the successive actuation of the assembly separate sections.

- Used-on assembly is hoisted to the surface with lifting speed limited to 3.1 miles per hour.

- A soluble ball is thrown into the well.

- Next stage to perform hydraulic fracturing is ready.